| MISSION & METHODS |

|

For 36 years, the primary mission of Straight Wire is to develop

and produce world class cables and related accessories, predominantly made in the USA, primarily for consumer audio and video enthusiasts.

Along the way – we have been privileged to be chosen for select

mobile ,studio, commercial, marine and avionic projects / applications as well as being the chosen OEM (Original Equipment Manufacturer) cable supplier for many well known brands. Straight Wire willingly

takes on custom projects that few other AV cables companies

would consider.

The philosophy of delivering all the music and a clear picture

at a reasonable price has helped us build and enjoy the respect,

admiration and confidence from consumers, dealers, industry

affiliates, press and many more.

The Straight approach to cables provides the truest sound and vision that the content creators intended for your relaxation & escape.

Link your system together with Straight Wire and uncover musical nuances & visual subtleties you've missed. You'll get more

entertainment from

all your existing AV gear and enjoy the

performance pleasures from new technologies and components

with Straight Wire. |

|

|

|

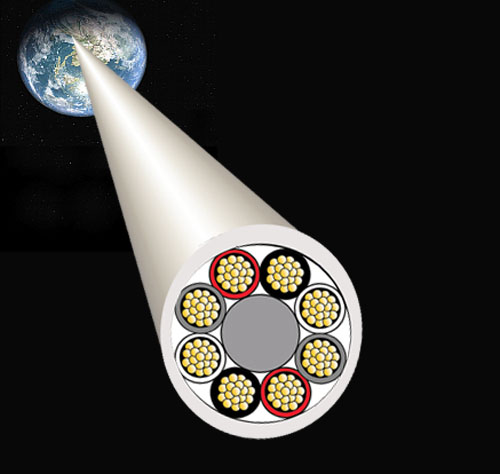

STRAIGHT WIRE RESEARCH & DESIGN

|

The Initial Design Process

After three decades of producing leading performance cables for

AV applications in over 50 international markets, Straight Wire

knows the parameters and development process to design new

cables. We constantly research, review & interpret the electrical

data on electronics and speakers to spot audio trends or tendencies. The latest AV formats and related equipment are evaluated so we

can develop cables ahead of the current standards to enable long lasting performance and compatibility.

New materials and refined processes are employed on an application specific and cost conscious approach to develop cables with great value. Our years of experience and knowledge enable us to address real life concerns for flexibility, strain relief, bending radius, connector depth/protrusion and many more. Factors such as conductor diameter, braid angle, stranding options, insulation resonance points and dozens of other variables are analyzed and addressed before prototypes are produced. |

|

|

|

The Listening Panel

After an audio cable's mechanical and electrical parameters have

been optimized on the drawing board, a limited quantity of cable is produced for the listening panel (in two or three color coded versions) composed of leading manufacturers, dealers, critics and consumers. Quantitative sonic evaluation reports are generated with a record of specific equipment used in the evaluation process. Solid state & tube gear, dynamic & planar speakers from many manufacturers are used

by the listening panel to establish a broad basis for the selection of

the final production version. |

|

|

|

Refinement & Tweaking

The listening panel's reports are carefully evaluated to select which of the prototype versions should be put into production. Sometimes additional prototypes are produced to achieve the sonic approval of

the listening panel while maintaining optimized electrical and mechanical parameters for broad applications.

Video cables are designed, prototyped and built to exceed mil-spec tolerances to ensure reliable, consistent performance. Premium conductors, insulation and shielding are chosen to ensure your

picture is worth a thousand words.

Straight Wire transcends other cables because of logical and methodical research and redesign efforts before a product is offered

to the customer. This process takes longer and costs more than

"quick trial and error" methods, but we're sure you'll see and

hear the difference with Straight Wire. |

|

|

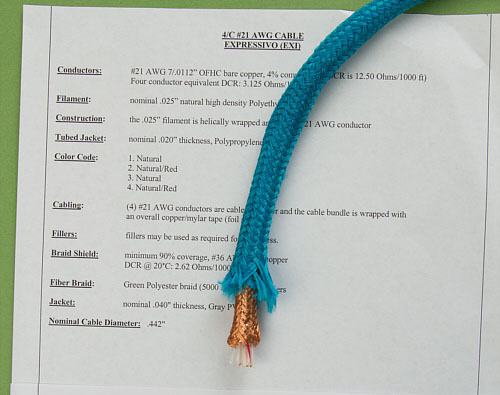

Special Manufacturing Tools

Only after our prototypes meet the exacting standards of measured accuracy and sonic fulfillment are they put into production. Even then,

we address interactive issues of temperature variation, tension, purity

of manufacturing environment and other elements critical to

maintaining the final design's integrity.

Slower more consistent line extrusions, Planar vs. Wardwell braiders where applicable, computer controlled take-off tensioning devices and many other special manufacturing tools are utilized in our

predominantly USA made cables. Highly skilled personnel watch over the bulk cable manufacturing and employ a cutting board that shows how each cable should look and measure at each stage of completion. |

|

|

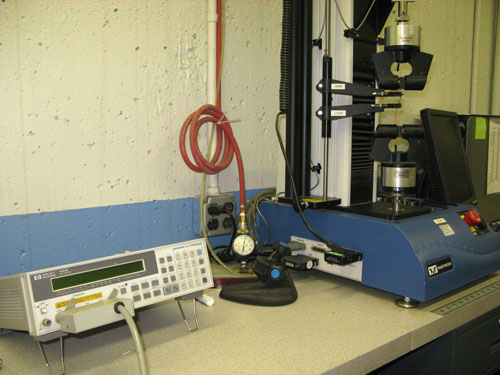

Terminations and QC

All terminations are completed to the exacting procedures of the

original reference design. Heavy gold plated, PTFE insulated connectors are terminated with silver solder in a carefully controlled environment. Our procedures are on par with jewelry making standards of precision and measured tolerances. The technicians making most of our cables have years of experience and are meticulous in their craftsmanship.

|

Our technicians cross check

all their assemblies with another highly skilled partner. Their mutual goal is to produce flawless cables, even if the process is more time consuming than expected. Magnification devices are used to inspect the final assembly followed

by a process of electrical measurements. |

|

|

|

| |

It is only after this time consuming process that we release our Lifetime Limited Warranty*

that is featured on all Straight Wire cables. |